Subtotal: $200.00

Product Description

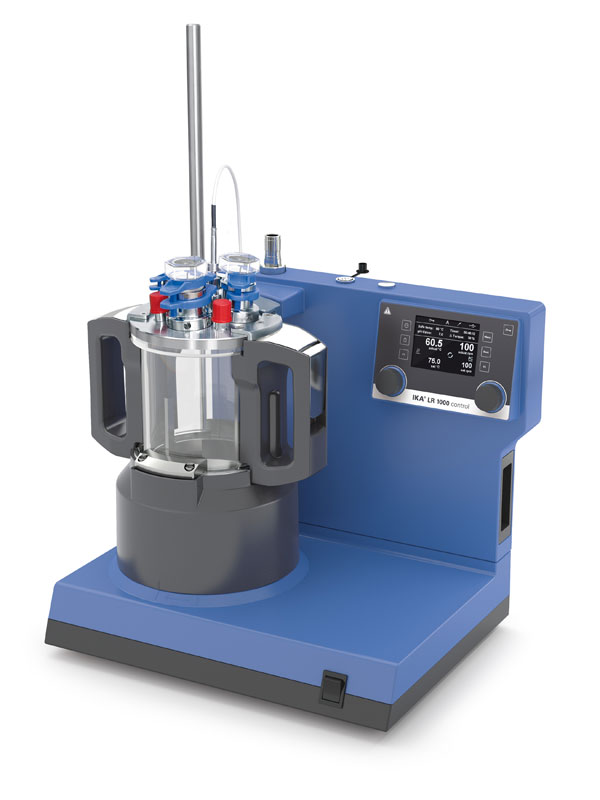

LR 1000 control Package

The LR 1000 control is a cost efficient, modular laboratory reactor designed for optimizing chemical reaction processes as well as for mixing, dispersing and homogenization applications at the laboratory scale. The system can be adapted quickly and easily for a wide range of applications and specific requirements. The reactor is especially designed for the unique applications requirements that define the cosmetic and pharmaceutical industries. The temperature of the medium can be as high as 120 ºC. The temperature of the heating source, which is located at the bottom of the vessel, is controlled accordingly to reach the set temperature inside the medium. A PT 100.30 temperature sensor and the corresponding receptacle LR 1000.61 for the lid are included with this package. Prominent features of the LR 1000 control system are the integrated pH sensor connection and the display interface. The latter allows for the display of all process-relevant data onto a PC, save data storage and control of the reactor. The software (accessory) allows for further adaptation of the overall system and processes.

Metals in contact with medium: stainless steel ( ALSI 316 L), FFKM, PTFE, PEEK, borosilicate glass 3.3

- Large easy to read TFT display for better image quality and easy navigation

- Integrated weighing funktion

- Torque trend measurement indicates changes in product viscosity

- Integrated pH sensor connection

- RS 232 and USB interface to operate the unit with the laboratory software labworldsoft

- Standard joint fittings on the lid: 2 x NS 29, 2x NS 14, 2 x GL 14 for flexible adaptation of further equipment

- Expandable for use with the ULTRA- TURRAX® T 25 digital (Accessory)

- Vacuum valve included with delivery

- Anchor stirrer with PTFE-scrapers

- Connections to attach a cooling source to the back of the unit

- Manual adjustable safety circuit

- Integrated safety shutdown when vessel or lid is removed from the base

Technical Data:

| Usable volume max. | 1000 ml |

| Usable volume with disperser tool min. | 300 ml |

| Usable volume without disperser tool min. | 500 ml |

| Working temperature max. | 120 °C |

| Attainable vacuum | 25 mbar |

| Viscosity max. | 100000 mPas |

| Speed range | 10 – 150 rpm |

| Support rod diameter (with integrated fastening on stand) | 16 mm |

| Material in contact with medium | AISI 316L, 1.4571, borosilicate glass 3.3, PTFE, PEEK, FFKM |

| Reactor vessel openings (units/standard) | 2x NS 29/32, 2x NS 14/23 & 2x GL 14 |

| Permissible ON time | 100 % |

| Temperature measurement resolution | 0.1 K |

| Nominal torque | 3 Nm |

| Heat output | 1000 W |

| Cooling medium permissible operating pressure | 1 bar |

| Weighing range max. | 2000 g |

| Weighing resolution | 1 g |

| Speed min (adjustable) | 10 rpm |

| Heating temperature max. | 180 °C |

| Adjustable safety circuit, upper temperature value | 225 °C |

| Adjustable safety circuit, lower temperature value | 47 °C |

| Adjustable safety circuit, upper temperature value deviation | 20 ±K |

| Adjustable safety circuit, lower temperature value deviation | 10 ±K |

| Cooling medium temperature min. | 3 °C |

| Set temperature resolution | 1 ±K |

| Heat control accuracy of medium with sensor | 0.2 ±K |

| Speed deviation | 5 ±rpm |

| Speed display | TFT |

| Heat control | TFT |

| Connection for ext. temperature sensor | PT 100 |

| Stirring element fastening | special output shaft |

| Torque display | yes |

| Torque measurement | trend |

| Timer | yes |

| Timer display | TFT |

| Speed control | 1 RPM steps |

| Type of cooling | flow |

| Temperature display | yes |

| Working temperature sensor | PT 100 |

| Safety temperature sensor | PT1000 |

| Working temperature display | TFT |

| Safety temperature display | TFT |

| Display for operation with ext. sensor | yes |

| Safety cutout | yes |

| Reversible direction of rotation | no |

| pH meter interface | yes |

| pH value display | TFT |

| Dimensions (W x H x D) | 443 x 360 x 295 mm |

| Weight | 16 kg |

| Permissible ambient temperature | 5 – 40 °C |

| Permissible relative humidity | 80 % |

| Protection class according to DIN EN 60529 | IP 21 |

| RS 232 interface | yes |

| USB interface | yes |

| Analog output | no |

| Voltage | 230 / 115 V |

| Frequency | 50/60 Hz |

| Power input | 1200 W |